Kentix MultiSensors are equipped with various individual sensors. To ensure optimum evaluation and functional cooperation of the sensors, please observe the following basic mounting instructions:

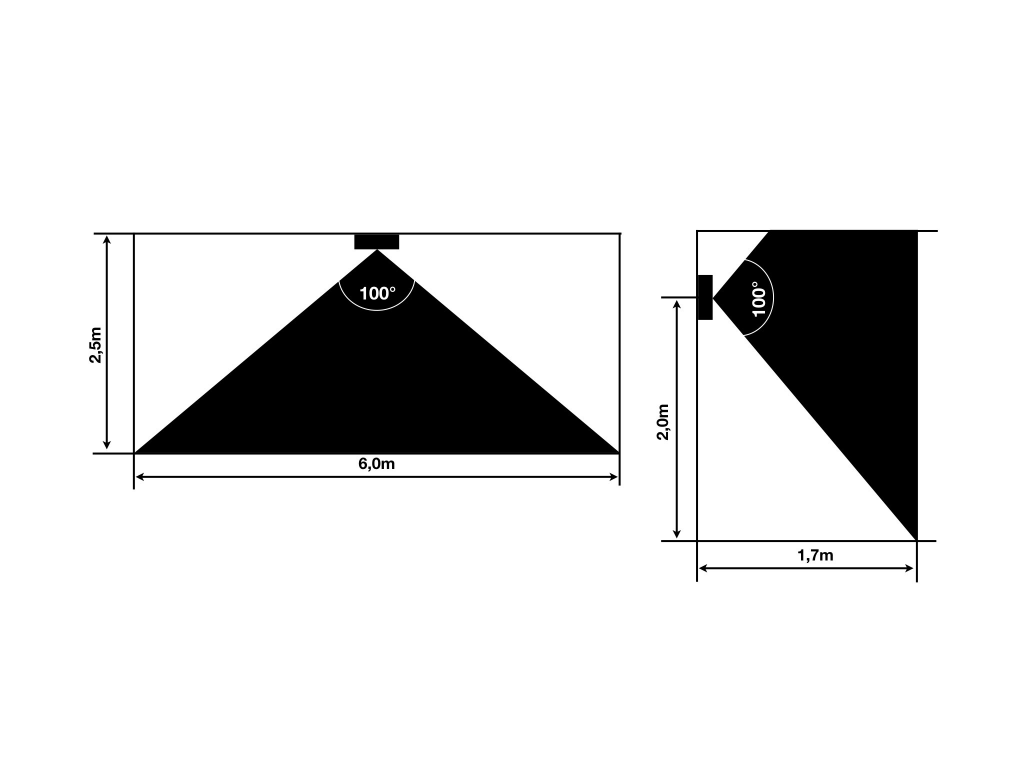

Detection range of the integrated PIR motion detector

Mounting instructions for MultiSensor TI

When mounting the Kentix MultiSensor-TI, it is important to consider the application for which the device is to be used and the area to be monitored. Based on this, attention must be paid to the following aspects before mounting the device.

When used for early fire detection

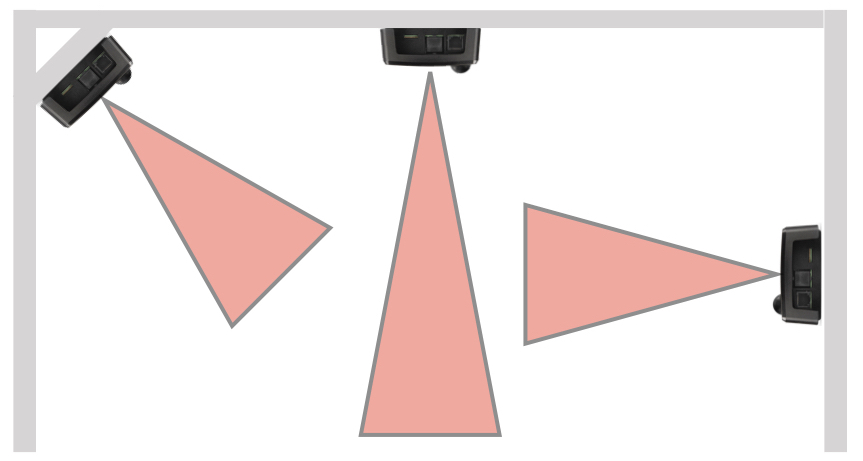

Alignment

The Kentix MultiSensor is oriented so that when viewed head-on, the lens is at the top. If this is not possible for certain reasons, the thermal image can be rotated in the web interface.

For early fire detection, the sensor can also be mounted on a wall at an angle or vertically. Optimal alignment is promising in this respect. It is advisable to align the center of the field of view. This can be done with the help of a warm object (candle, coffee cup, hot plate, etc.) and the live image of the infrared sensor. The scale that can be switched on in the live image can help with correct positioning.

Mounting/mounting height

Angle: Height: Area: 638.30 x 638.30 cm (40.74 m²) Pixel size: 19.95 x 19.95 cm (397.87 cm²) 300 cm 638.3 cm KMS TI – 90° Grid: 32×32 = 1024 638.3 cm 638.3 cm 19.95 19.95 cm KMS TI –

For early fire detection we recommend a mounting height between 0.5 m and 5 m! The pixel size of the thermal image must always be taken into account for the mounting height. For more information, refer to the MultiSensor TI operating instructions .

The supplied mounting bracket is used for attachment. Optionally, mounting brackets can also be used for this purpose.

Basics of infrared measurement technology

Infrared measurement technology is the non-contact measurement of surface temperatures. Any object with a temperature above 0 Kelvin (-273.15 °C) emits infrared waves. These light waves travel in a wavelength range from 780 nm to 3 mm.

Infrared measurement is distinguished between three ranges:

- Near Infrared (NIR) region: Includes wavelengths between 750 nm to 2.5 μm

- Mid-infrared range (MIR): Includes wavelengths between 2.5 μm to 25 μm

- Far Infrared Range (FIR): Includes wavelengths between 25 μm to 3 mm

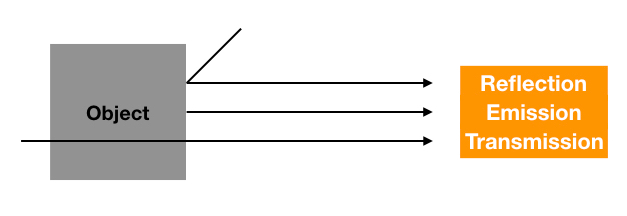

Emission, reflection and transmission

Emission is the radiation emitted by the measuring body. The emissivity (ε) describes the ability of an object to emit infrared radiation. The emissivity of the skin, for example, is on average ε=0.98.

Reflection describes external radiation which is reflected by the measuring body. The reflectance (R) defines the ability of an object to reflect infrared radiation from its surface. This depends on the surface finish as well as the material.

Transmission describes the ability of a measuring body to transmit infrared radiation. The transmittance (τ) depends on the thickness and type of material.

Advantages of infrared measurement technology

- Infrared measurement is particularly suitable for dynamic and rapidly changing processes

- State-of-the-art technology with reliable microprocessor technology

- Temperatures of very hot temperatures can be measured

- Temperature measurement without influencing the contact surface

- Contactless measurement of temperatures of various measuring objects

Fields of application of the infrared measurement

Temperature measurement and environmental monitoring using infrared sensors offers a wide range of possibilities.

- Building thermography

- Industrial thermography

- Energy industry

- Quality assurance

- Environmental protection

- Medicine

In all these areas, monitoring various objects with infrared sensors can be useful.

Temperature measurement by infrared radiation

As already described, every object above the absolute zero point of 0 Kelvin (=-273.15 °C), emits infrared radiation. The higher the temperature of the measured object, the higher its infrared radiation.

This radiation can be recorded with an infrared pyrometer and output as a temperature value. The radiation emitted by the target is picked up by a lens of the pyrometer. The lens projects the radiation onto a sensor.

This sensor converts the infrared radiation into an electrical signal. This is amplified and evaluated by a microprocessor. This processor calculates the temperature of the measured object from the recorded radiation and the ambient radiation, taking into account the emissivity.

Measurement with infrared sensors is an optical measurement method. For this reason, care must be taken to ensure a clean measurement environment. Dust, steam, etc. are disturbance variables and can lead to deviations and measurement errors.